CONDENSATE REMOVAL

BlueDiamond® Solution for HVACR engineers

The Importance of Effective Condensate MANAGEMENT in air conditioning/ hvacr Systems

Air conditioning units are essential for maintaining comfortable indoor climates, especially in warmer seasons. However, one common by product of cooling processes is condensate—water that forms as moisture from the air condenses on the evaporator coil. This water needs to be effectively removed to prevent issues like water damage, mould growth, and reduced air conditioning efficiency. Efficient condensate removal not only preserves the longevity of your AC unit but also enhances indoor air quality and system performance.

why is CONDENSATE removal important

Prevents water damage: Accumulated water can overflow from the condensate pan, causing water damage to surrounding areas, including walls, ceilings, and floors.

Reduces mould growth: Excess moisture can lead to mould growth within the unit, which can spread to the air ducts and affect indoor air quality.

Maintains air conditioning efficiency: If condensate isn’t removed, it can hinder airflow and reduce the efficiency of the AC unit, leading to higher energy costs.

Avoids costly system shutdowns: Some AC units have float switches that will shut down the system if water levels get too high, resulting in unexpected service interruptions

How is condensate formed?

Condensate is a natural result of the air conditioning process. As warm, humid air passes over the evaporator coil, the coil’s cold temperature causes moisture in the air to condense, forming water droplets. This water eventually collates in a condensate pan, then directed away from the unit through a condensate drain line or tube. If the line becomes blocked or damaged, water can back up and lead to a host of issues such as leaks. These environments are not pure, meaning that dust, dirt, mould and algae frequently builds up in the system and needs to be maintained and cleaned regularly unless its regularly removed via a pump or other means.

Common challenges for engineers

Clogged drain lines: Dirt, algae, and other particles can accumulate in the drain line, blocking the flow of water. Regular cleaning can help prevent this which comes at a cost and also time.

Damaged or disconnected drain lines: Cracks or disconnections in the drain line can lead to leaks and water damage.

Improperly sloped lines: Gravity-based systems rely on a precise slope to drain water. If the line isn’t installed correctly, it can lead to water pooling.

Adopting energy efficient solutions: Evaporator pans are not only costly but also consume large amounts of power, making them an environmentally unfriendly option.

Limitations on pump location: Tank and piston pumps must be installed in levelled positions, which can be challenging and impractical in space-constrained environments.

options for condensate removal

CONDENSATE REMOVAL PUMP

Air conditioning systems are often installed in locations where the outlet for gravity drainage is too far away, making a condensate removal pump necessary. As the preferred and most convenient solution for engineers, the pump collects the condensate and transfers it to a drain or discharges it outside the building. Our answer to this challenge is the BlueDiamond range of condensate pumps – self-priming, capable of running dry, and completely valveless, they require no regular maintenance, unlike many other pump brands on the market. For an even more reliable and intelligent solution, we recommend pairing selected models with CondenSense™ sensors, ensuring optimal performance and early detection of potential issues.

DAIRY CABINET PUMP

Supermarket fridge cabinets often lack easy access to gravity drainage, making reliable condensate removal essential. The ArctikBlue® Diary cabinet pump offers a compact, low-maintenance, low-running cost solution designed specifically for commercial and industrial scale refrigeration. Built for efficient, continuous operation, the ArctikBlue cabinet pump delivers dependable performance with minimal upkeep. Paired with our CondenSense™ smart sensor technology for optimal system efficiency, it will only turn the pump on when required, adapting to the variable outputs made by fridges.

ALTERNATIVE options

GRAVITY DRAINAGE

Gravity drainage is the simplest method for condensate removal. It relies on a correctly sloped drain line to allow water to flow naturally away from the unit without mechanical assistance. When properly installed, this method is highly energy-efficient and silent. However, over time, drain lines can become blocked with algae, dirt, or debris, reducing reliability and requiring frequent maintenance. Additionally, gravity drainage is typically limited to external discharge, where water can drip onto surfaces, leaving unsightly algae stains and exposure to environmental factors such as freezing temperatures.

EVAPORATOR PANS

Some refrigeration units are equipped with evaporative condensate removal systems, where the condensate is evaporated within the system itself, eliminating the need for drainage lines. However, this process is equivalent to continuously boiling a kettle, resulting in high energy consumption and making it one of the least environmentally friendly solutions on the market. In addition to poor energy efficiency, evaporator pans emit contaminated condensate vapour into the atmosphere, creating an unhygienic environment for customers visiting stores.

Used in retail supermarkets only

OUR MOST EFFECTIVE solutions

To make pump selection easier, BlueDiamond uses a simple and reliable guideline:

- For every 1 kW of cooling, your system produces approximately 0.264172 G of condensate per hour.

- For example, a 10 KW air-conditioning unit will generate around 2.64172 G/hr of condensate.

Use this information to select the correct pump for your setup. Select the unit that matches the KW rating of your air-conditioning unit to find the most suitable pump for your needs.

MICROBLUE

| Max Flow: | 1.3 G/HOUR (5L/HOUR) |

| Max Head: | 5 M (16 FT) |

| Max Lift: | 2 M (6FT) |

| Sound: | 17 dB(A) |

| Unit: | 3.5 KW (18000 BTU) |

Available in UK, EU & USA

MICROBLUE + FASCIA

| Max Flow: | 1.3 G/HOUR (5L/HOUR) |

| Max Head: | 5 M (16 FT) |

| Max Lift: | 2 M (6FT) |

| Sound: | 17 dB(A) |

| Unit: | 3.5 KW (18000 BTU) |

Available in USA only

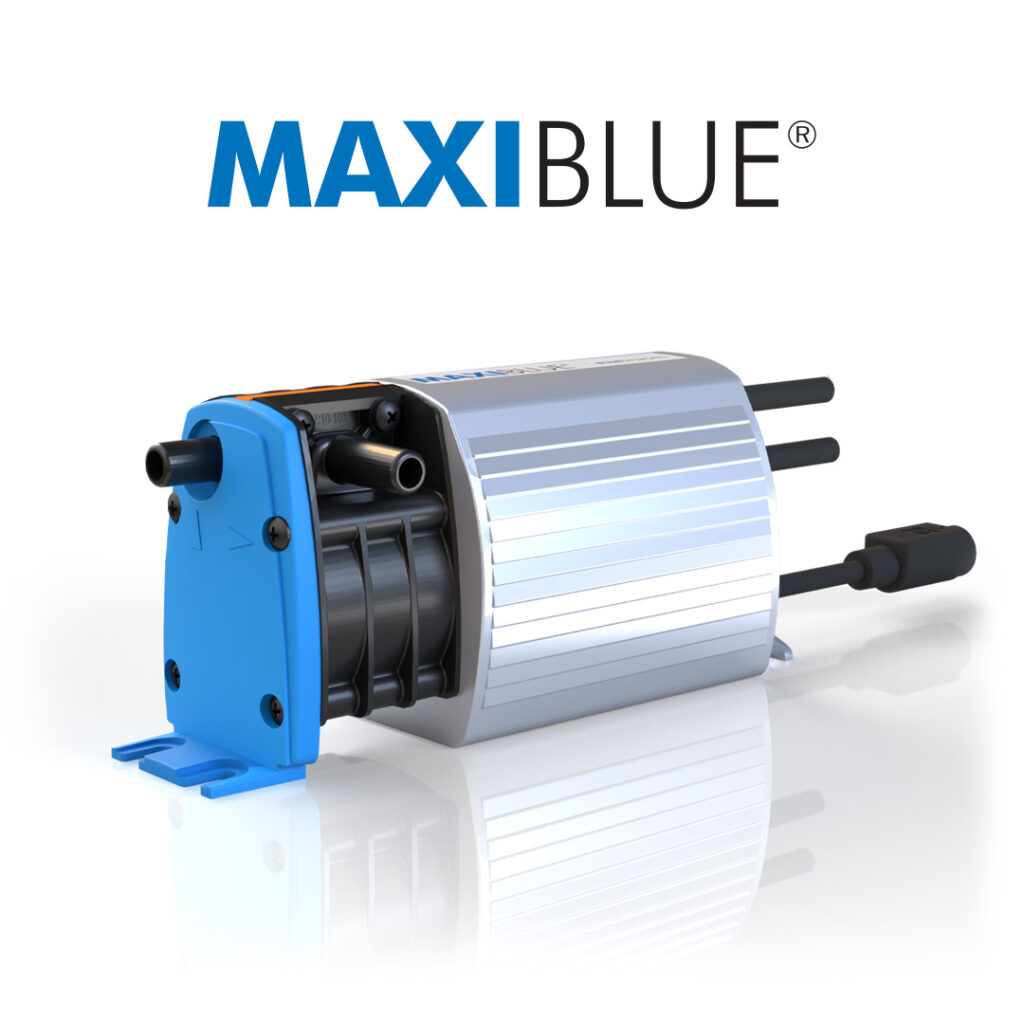

MAXIBLUE

| Max Flow: | 3.7 G/HOUR (14l/HOUR) |

| Max Head: | 8 M (23 FT) |

| Max Lift: | 8 M (16.5FT) |

| Sound: | 21 dB(A) |

| Unit: | 8.0 – 14.0 KW (48000 BTU) |

Available in UK, EU & USA

MEGABLUE

| Max Flow: | 12.6 G/HOUR (48 L/HOUR) |

| Max Head: | 20 M (66 FT) |

| Max Lift: | 8 M (23 FT) |

| Sound: | 23 dB(A) |

| Unit: | 14.0-50.0 KW (48000 – 170000BTU) |

Available in UK, EU & USA

ARCTIKBLUE

| Max Flow: | 12.6 G/HOUR (48 L/HOUR) |

| Max Head: | 20 M (66 FT) |

| Max Lift: | 8 M (23 FT) |

| Sound: | 23 dB(A) |

| Unit: | 14.0-50.0 KW (48000 – 170000BTU) |

Available in UK, EU & USA